sleeve packing machine

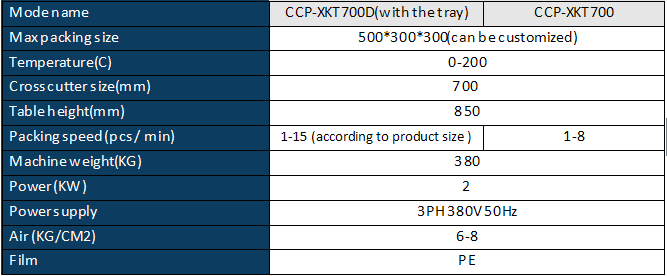

specifications

Features

Application

Transaction story of sleeve shrink packing machine

This story is from Vietnam. One of my vacuum cleaner customers came to our company in April 2018 and proposed to buy a cuff type shrink wrapping machine. The customer’s situation was as follows: he had bought a sleeve shrink packing machine, and the back section was equipped with a shrinking machine. However, after the machine was transported to Vietnam, it has not been successfully debugged, and the product shrinkage is not good. At present, he Our business volume is very large. If we can only use manual packaging, the efficiency is too slow, too much labor is wasted, and the cost is not cost-effective. The customer said: Although labor in Vietnam is not expensive, more than a dozen people just want to shrink the packaging, which is too much pressure for them. The production management is difficult to manage because of too many personnel. Therefore, they need to purchase a packaging machine as quickly as possible.

The customer sent us their technical proposal, and the engineer put forward several problems to the customer after discussion according to the plan: 1. We can’t meet the power requirements of the customer. The cuff packer uses PE film to shrink. When shrinking, the PE film is baked in the oven at high temperature and then shrinks back. If the power is small and the product size is large, it can not be finished 2. The size of the customer’s product is relatively large, the machine should be non-standard customized, and the production cycle should be adjusted to 30 working days; 3. Sample requirements, we require customers to provide samples of each product, at least 5 pieces, otherwise, we can not complete the debugging. These three points communicate with customers, and customers respect our ideas. The order went down so smoothly.

After the customer placed an order, we finished the production as scheduled and successfully delivered the machine to the Vietnam factory. There was a little incident during the debugging. When the customer’s engineer adjusted the cutter guard board, he did not operate properly and broke the electric wire of the electric heating tube inside the knife. We made the accessories as quickly as possible and sent it to the guest by express delivery, although there was a little incident in the middle However, the use of the guests was very smooth. So far, there is no problem with the machine.

After this cooperation, the guests are very satisfied with our technology. Although they think that we should save electricity, save energy, etc., when communicating, they will give them a good answer to the final contraction effect. When making the sleeve shrink packing machine, we should consider the weight of the product, the thickness of the film material and the size of the product to customize the shrinkage furnace at the back, instead of blindly saving energy. Perfect contraction is what we can offer our guests.When a guest makes a request, he is unknown. He just points out the problems of the machine in front of him, hoping that you can receive all the points that he wants to improve. However, in fact, to do a good job of the machine, we must have a good understanding of all the processes and the principle is very clear. Therefore, when making this sleeve shrink packing machine, we adhere to the important technical indicators, so that customers can enjoy a good product.

sleeve packing machine for mineral water

sleeve packing machine for tape

sleeve packing machine for refrigerator

sleeve packing machine for toothpaste